In today’s industrial landscape, the demand for superior insulation solutions is paramount, especially in high-temperature applications. High-Temperature Ceramic Fiber Modules emerge as a groundbreaking choice, offering unparalleled benefits that can lead to significant operational efficiencies.

One of the defining features of these modules is their ability to provide exceptional thermal insulation. This translates to effective heat retention, which importantly minimizes energy losses. Enhanced insulation leads to improved operational efficiency, making these modules vital across various industries.

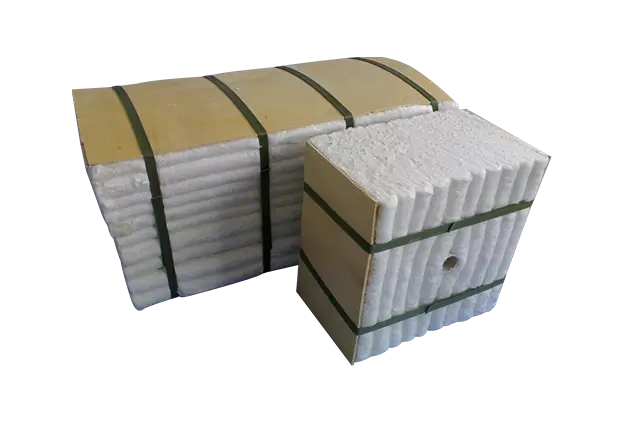

The lightweight design of ceramic fiber modules makes them easy to handle and install. Their low bulk density does not compromise their robustness; in fact, they possess high mechanical strength, allowing them to withstand extreme operational conditions with ease.

These modules are tailored for a variety of industries, including petrochemical, steel, and ceramic. Their versatility ensures they meet specific insulation needs, enhancing safety and energy efficiency. Whether it’s a tunnel kiln or a coking furnace, these modules fit effortlessly into myriad applications.

Installation speed is a critical factor in minimizing downtime and costs. High-temperature ceramic fiber modules are designed for quick installation, facilitating seamless deployment in various projects. This aspect not only saves time but also reduces labor costs significantly.

The shift towards energy-efficient operations demands innovative solutions, and High-Temperature Ceramic Fiber Modules stand out as a top contender. Their exceptional insulation properties, coupled with lightweight, durable design and versatility, make them essential in modern thermal applications. By investing in these modules, businesses can ensure not only a reduction in energy costs but also a commitment to operational excellence and safety.